Esta subasta ha terminado.

Detalles

Fabricante

Lewa

Año de construcción

2006

Descripción

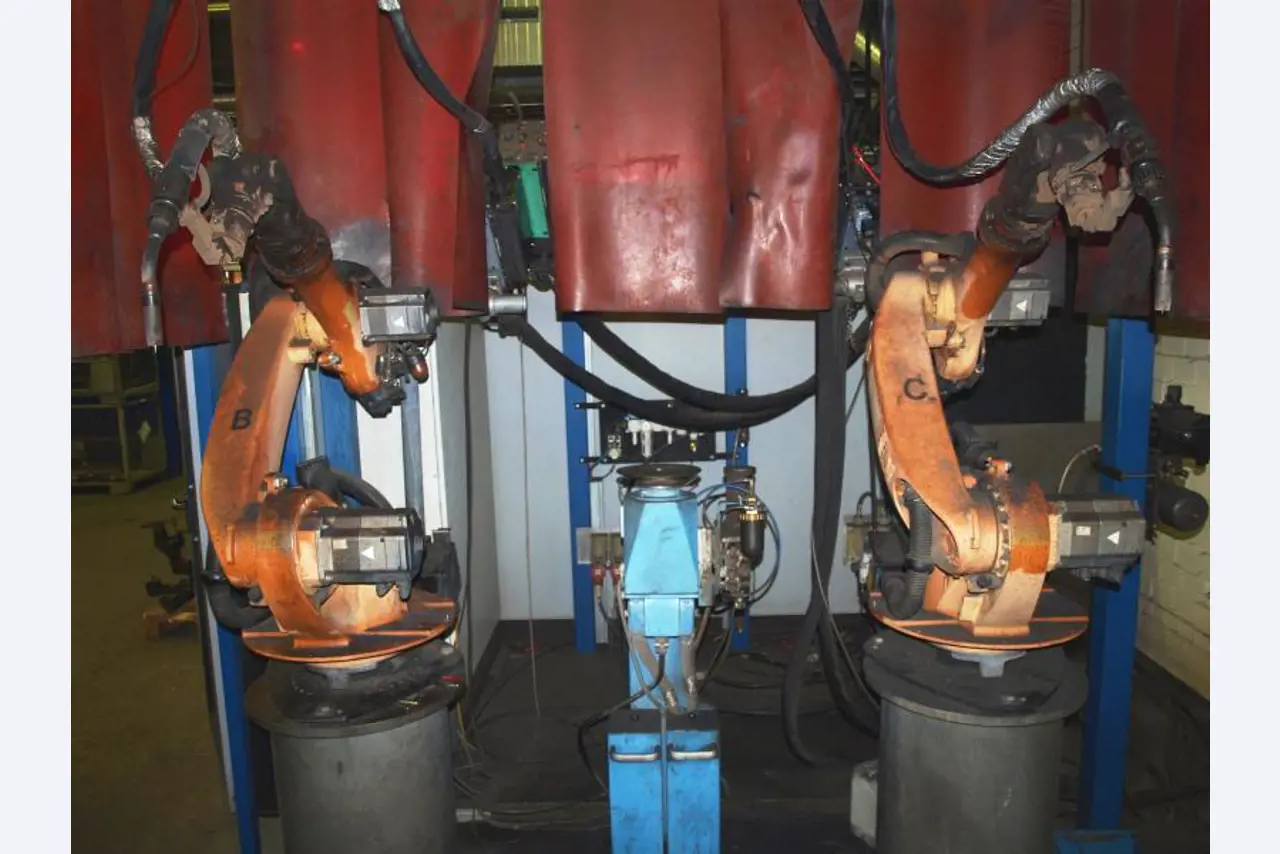

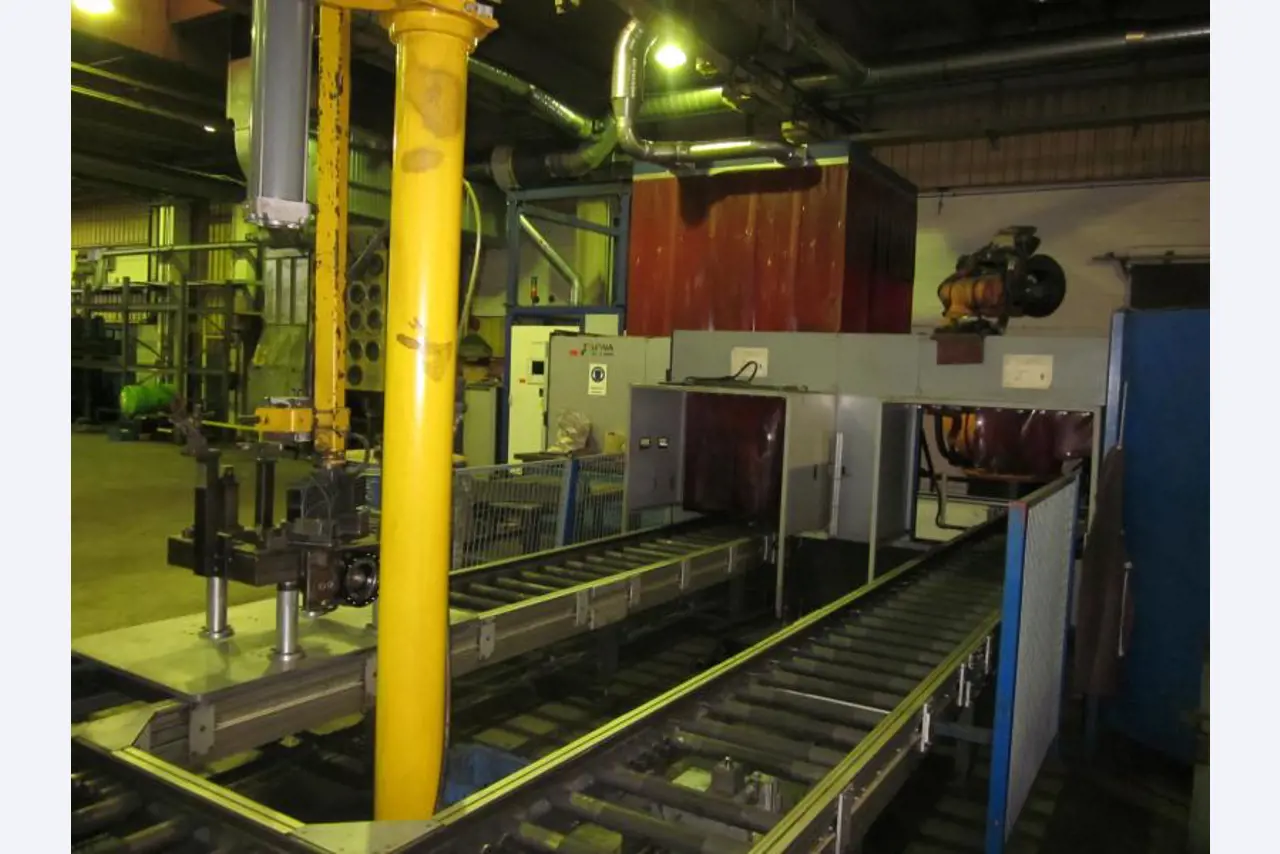

consisting of: handling robot, make Kuka, 6 Achsen, type KR 500-2, ser.-No. 796072, 2 Welding robot, make Kuka, type KR 6 ARC, ser.-No. 880227/880226, 2 welding sources, make Fronius, type TP 4000, sand blasting machine for cleaning the welding tips, electro roller conveyor system, make Krups, U- shaped, lenght approx. 8.000 mm, width approx. 3.000 mm, for work-piece palettes approx. 600 x 800 mm, control, make Siemens, type S7, 2 component manipulators, make Vesa

additional information: Welding equipment for large assemblies (up to approx. 180kg) with large weld lengths and complex structures f.e. like frames, cross and side members. Due to the robotcontrolled parts handling system an optimal welding position is always possible. The double synchronous welding robots achieve a high level of productivity and allow a optimum-warpage welding process. Due to the clever arrangement of the stitching places it is possible to configure a highly flexible single piece flow welding cell or a series welding line that is targeting for high parts output.

additional information: Welding equipment for large assemblies (up to approx. 180kg) with large weld lengths and complex structures f.e. like frames, cross and side members. Due to the robotcontrolled parts handling system an optimal welding position is always possible. The double synchronous welding robots achieve a high level of productivity and allow a optimum-warpage welding process. Due to the clever arrangement of the stitching places it is possible to configure a highly flexible single piece flow welding cell or a series welding line that is targeting for high parts output.

Ubicación

- 59229 Ahlen, Lindweg 25/ Schweißen

Partes de esta página han sido traducidas automáticamente. Se aplica el texto original en alemán.

Su asesoramiento personalizado

Nuestros expertos estarán encantados de asesorarle. Llame al +49 40 355059 -132 o escriba a service@netbid.com