Foundry machines (mould making, robotized die casting cells, PCD tools, and forging technology)

- Advance notice

- #18327

- Video

Dates

Auction Date

First quarter 2025

Documents

Description

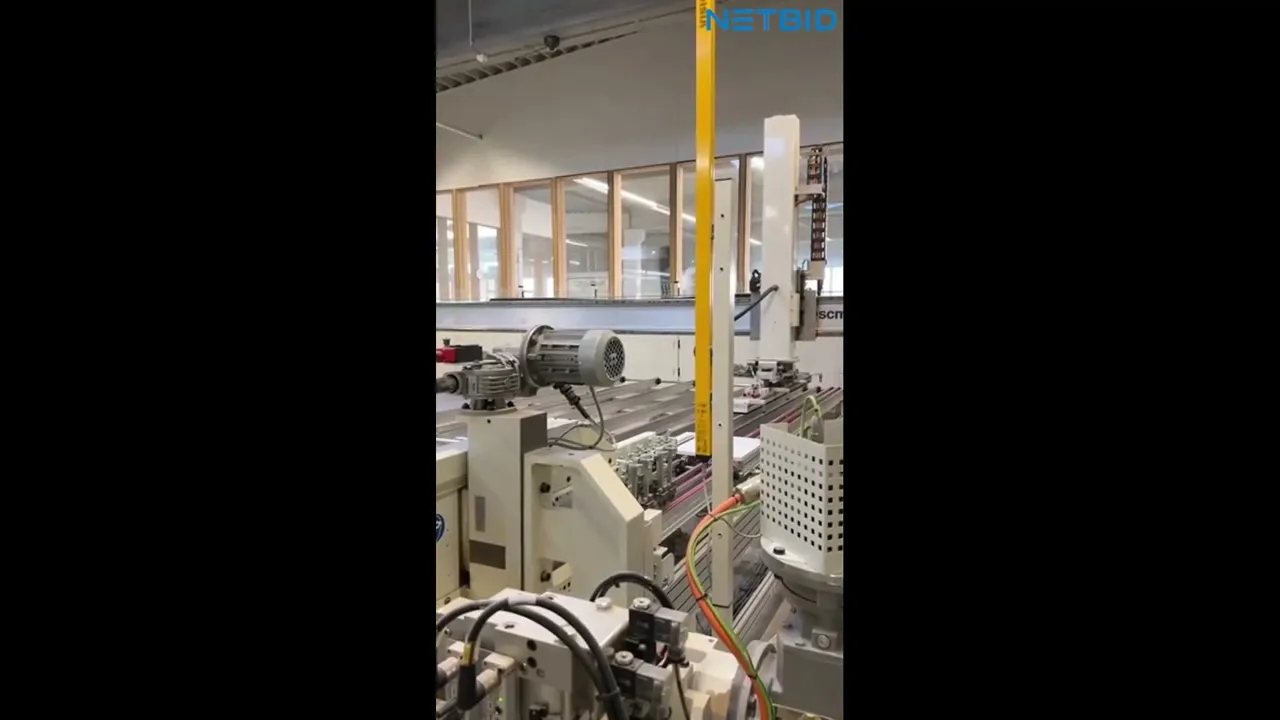

On behalf of the insolvency administrator, we are auctioning online against the highest bid the entire assets of Mariborska Livarna Maribor in the field of mould making with HSC technology, robotized die casting cells, PCD tools for diamond cutting and forging technology with high-speed automatic machines.

Location

- MLM d.d.

Oreško nabrežje 9

SL-2000 Maribor (Slowenien)

Catalog Excerpt

Put up for auction:

All company assets, including all movable and immovable assets.

Commercial property in the Melje industrial zone, Maribor.

The complex includes:

MLM manufactures aluminum castings and brass forgings. Die casting and forging processes are used for complex castings. Die-cast parts are precise, finished, tested and ready for assembly. The main customers come from the automotive, electrical, mechanical engineering and white goods industries.

Technologies:

Capacities:

Design (CAD/CAM):

Development of prototypes and series tools, trimming devices and 3D modeling. Supported by Pro/Engineer, CATIA and AutoCAD.

Special features:

Modern technologies ensure maximum precision and efficiency in all production steps.

All company assets, including all movable and immovable assets.

Commercial property in the Melje industrial zone, Maribor.

The complex includes:

- 41,507 m2 total area, including: - 3,920 m2 of office space

- 52,525 m2 plot area

- 37,587 m2 industrial space and canopies

MLM manufactures aluminum castings and brass forgings. Die casting and forging processes are used for complex castings. Die-cast parts are precise, finished, tested and ready for assembly. The main customers come from the automotive, electrical, mechanical engineering and white goods industries.

Technologies:

- Mould making with HSC technology

- Robotized die casting cells

- PKD tools for diamond cutting

- Forging technology with high-speed automatic machines

Capacities:

- Die casting foundry: 8,000 t/year, 14 machines, castings 0.1-10 kg

- Forge: 2,500 t/year, forging presses up to 400 t

- Machining: CNC centers with 3-5 axes

Design (CAD/CAM):

Development of prototypes and series tools, trimming devices and 3D modeling. Supported by Pro/Engineer, CATIA and AutoCAD.

Special features:

Modern technologies ensure maximum precision and efficiency in all production steps.

Parts of this page have been machine translated. The German original text applies.

14 / 30 Auctions

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com