Part of the Auction Machines and technical systems in the field of plastic injection molding (1600 - 23000 kN)

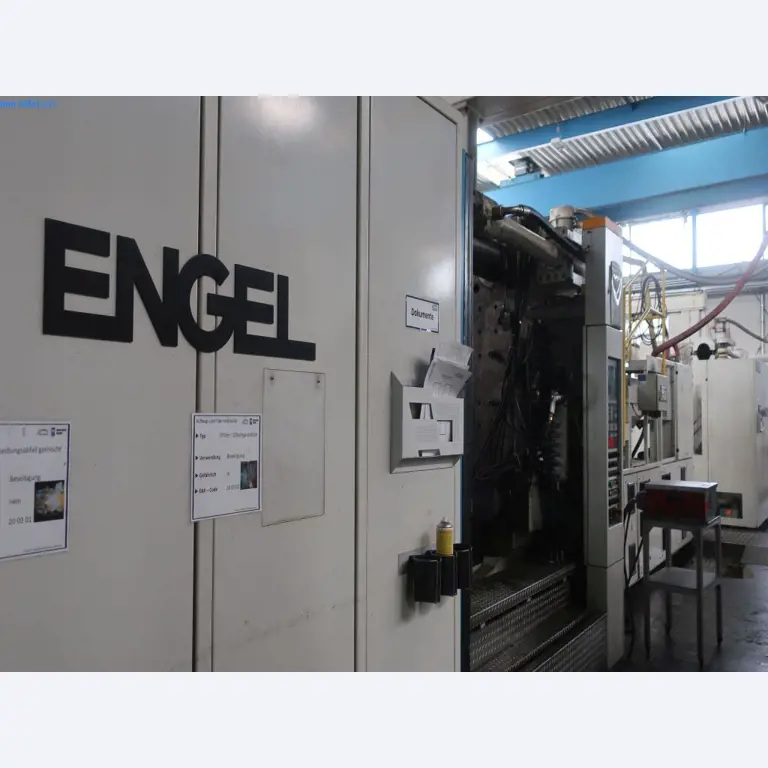

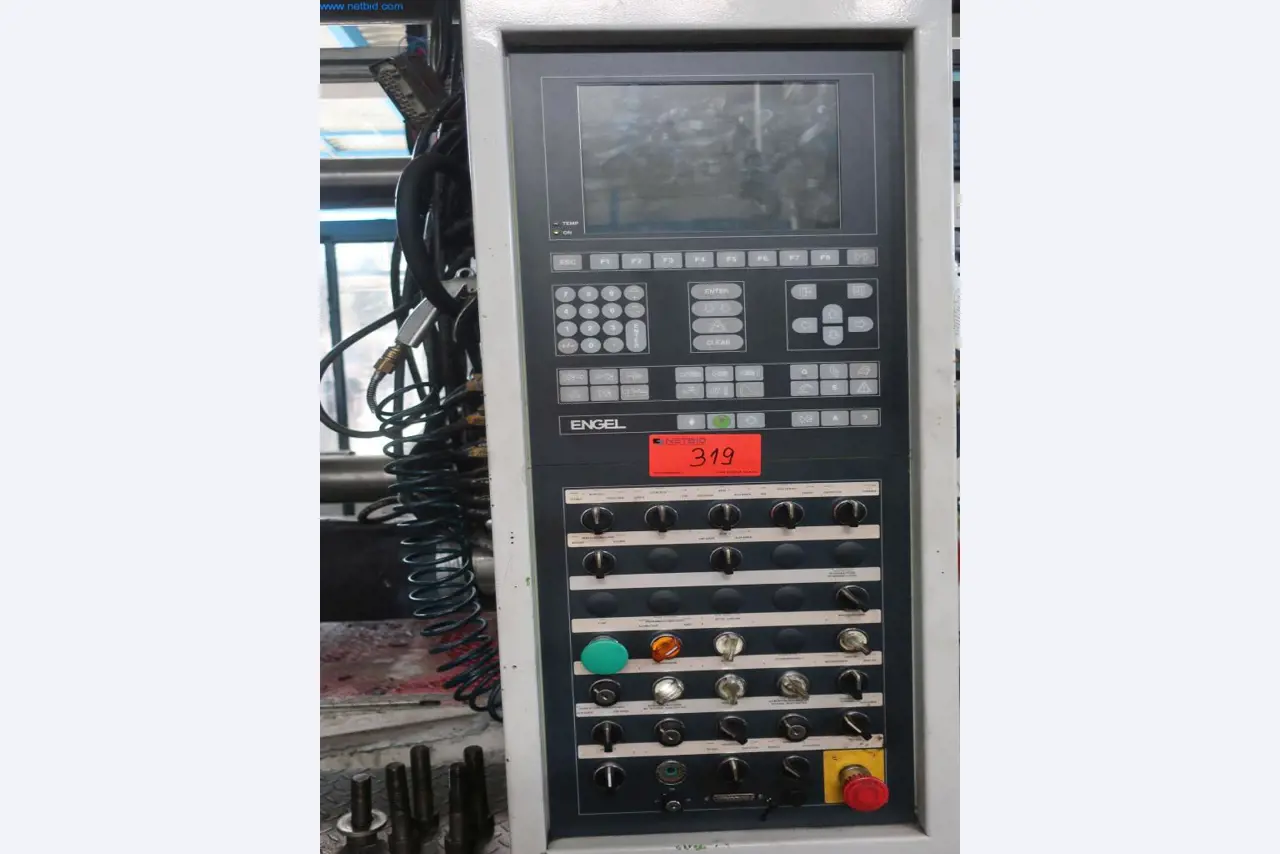

Injection molding machine - Surcharge under reserve Engel Duo 7050/1000

LIVE #16329-319

This auction has ended.

Details

Product Type

Engel

Type

Duo 7050/1000

Construction Year

2002

Description

The acceptance of the bid is done with the consent of the owner.

SN 46387, clamping force 10,000 kN, tie bar spacing horizontal/vertical 1,400/1,150 mm, clamping platen horizontal/vertical 2,000/1,830 mm, mold installation height max./min. 1,200/400 mm, mold opening distance 1,800 mm, total mold weight max. 18,000 kg, centering DS/AS 250/250 mm, crosshead thread M24, injection pressure 16,500 N/cm², injection volume 4,160 cm³, screw Ø 120 mm, cascade 12-fold, core pulls FAP/BAP 0/2, heating circuits Na/PSG 16/60, connected load 340 kW, machine weight 65,000 kg, max. Operating hours 04.798, linear demoulding robot, make Engel, type ERC A4/XXX, year 2002, SN 11245, protective housing, integr. mould cooling system, make Oni, type Rhytemper

Accessories: belt conveyor, W 1,000 mm, L 5,000 mm, elevated, mobile, Z-conveyor, W 250 mm, L 7,000 mm, cleated belt conveyor, make Interroll, belt width 300 mm, total length approx. 2.000 mm, cranked, underframe, mobile, granulate mill, make Romatec, without type plate, hot runner control unit, make PSG, type RSL 98/16, year 1996, SN 406, 16 channels, temperature control unit (37), make. Remak, type TRW 95 EWR 27,0 MRS, year 2006, SN 805745/01, nominal temperature 95°C, connected load 29,5 kW, temperature control unit (38), make Remak, type TRW 95 EWR 27,0 MRS, year 2005, SN 22971 805122/02, nominal temperature 95°C, connected load 29,5 kW, hot runner control unit, make PSG, type HR18, SN 250603098, 18 channels, connected load 42 kW

SN 46387, clamping force 10,000 kN, tie bar spacing horizontal/vertical 1,400/1,150 mm, clamping platen horizontal/vertical 2,000/1,830 mm, mold installation height max./min. 1,200/400 mm, mold opening distance 1,800 mm, total mold weight max. 18,000 kg, centering DS/AS 250/250 mm, crosshead thread M24, injection pressure 16,500 N/cm², injection volume 4,160 cm³, screw Ø 120 mm, cascade 12-fold, core pulls FAP/BAP 0/2, heating circuits Na/PSG 16/60, connected load 340 kW, machine weight 65,000 kg, max. Operating hours 04.798, linear demoulding robot, make Engel, type ERC A4/XXX, year 2002, SN 11245, protective housing, integr. mould cooling system, make Oni, type Rhytemper

Accessories: belt conveyor, W 1,000 mm, L 5,000 mm, elevated, mobile, Z-conveyor, W 250 mm, L 7,000 mm, cleated belt conveyor, make Interroll, belt width 300 mm, total length approx. 2.000 mm, cranked, underframe, mobile, granulate mill, make Romatec, without type plate, hot runner control unit, make PSG, type RSL 98/16, year 1996, SN 406, 16 channels, temperature control unit (37), make. Remak, type TRW 95 EWR 27,0 MRS, year 2006, SN 805745/01, nominal temperature 95°C, connected load 29,5 kW, temperature control unit (38), make Remak, type TRW 95 EWR 27,0 MRS, year 2005, SN 22971 805122/02, nominal temperature 95°C, connected load 29,5 kW, hot runner control unit, make PSG, type HR18, SN 250603098, 18 channels, connected load 42 kW

Location

- 38228 Salzgitter, John-F.-Kennedy-Str. 50/ Produktionsgebäude/ Halle 2/ Spritzguss

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com