Part of the Auction Machines and technical systems in the field of plastic injection molding (1600 - 23000 kN)

Injection molding machine - Surcharge under reserve Engel Duo 16050/2300

LIVE #16329-403

This auction has ended.

Details

Product Type

Engel

Type

Duo 16050/2300

Construction Year

2002

Description

The acceptance of the bid is done with the consent of the owner.

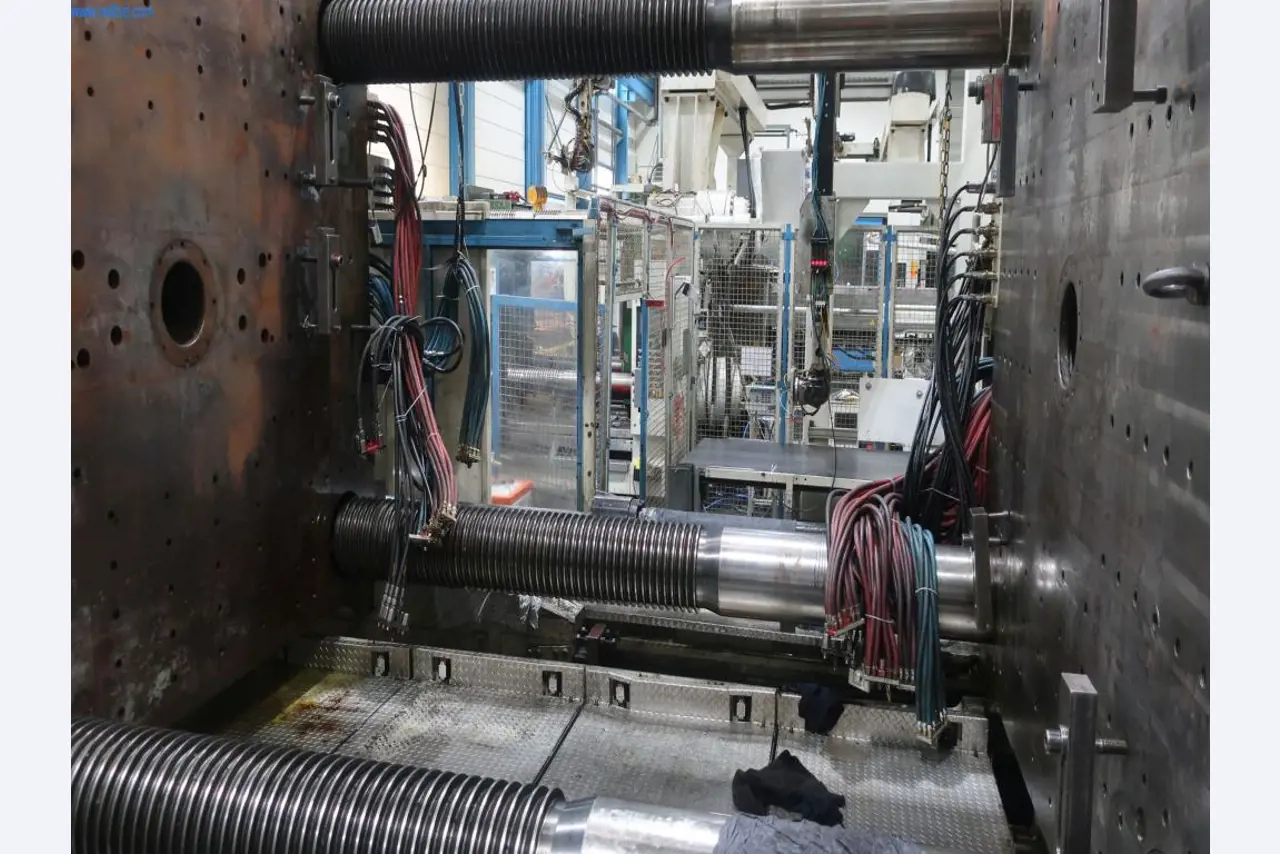

SN 47189, clamping force 23,000 kN, tie bar distance horizontal/vertical 2,000/1,600 mm, clamping platen horizontal/vertical, 2,900/2,500 mm, mold installation height max./min. 2,000/800 mm, mold opening stroke 3,000 mm, total mold weight max. 54 t, centering DS/AS 250/250 mm, crosshead thread M30, injection pressure 16,400 N/cm², injection volume 8,870 cm³, screw Ø 135 mm, cascade 15-fold, core pulls FAP/BAP 2/3, heating circuits Ma/PSG 40/12, metal separator, connected load 560 kW, machine weight 141 t, max. Operating hours 05.614, control, make Engel, linear handling robot, make Engel, type ERC XXL, protective enclosure

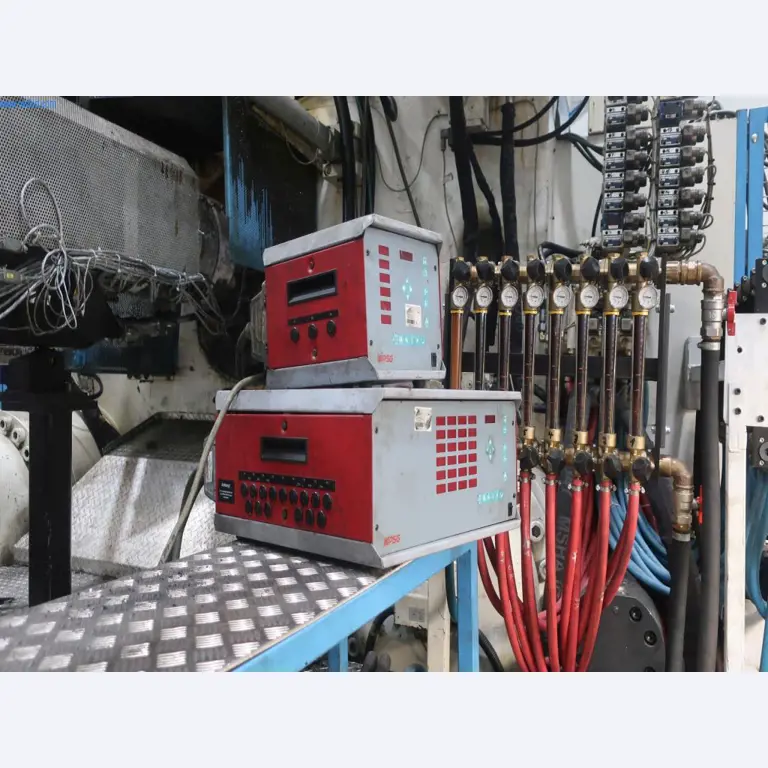

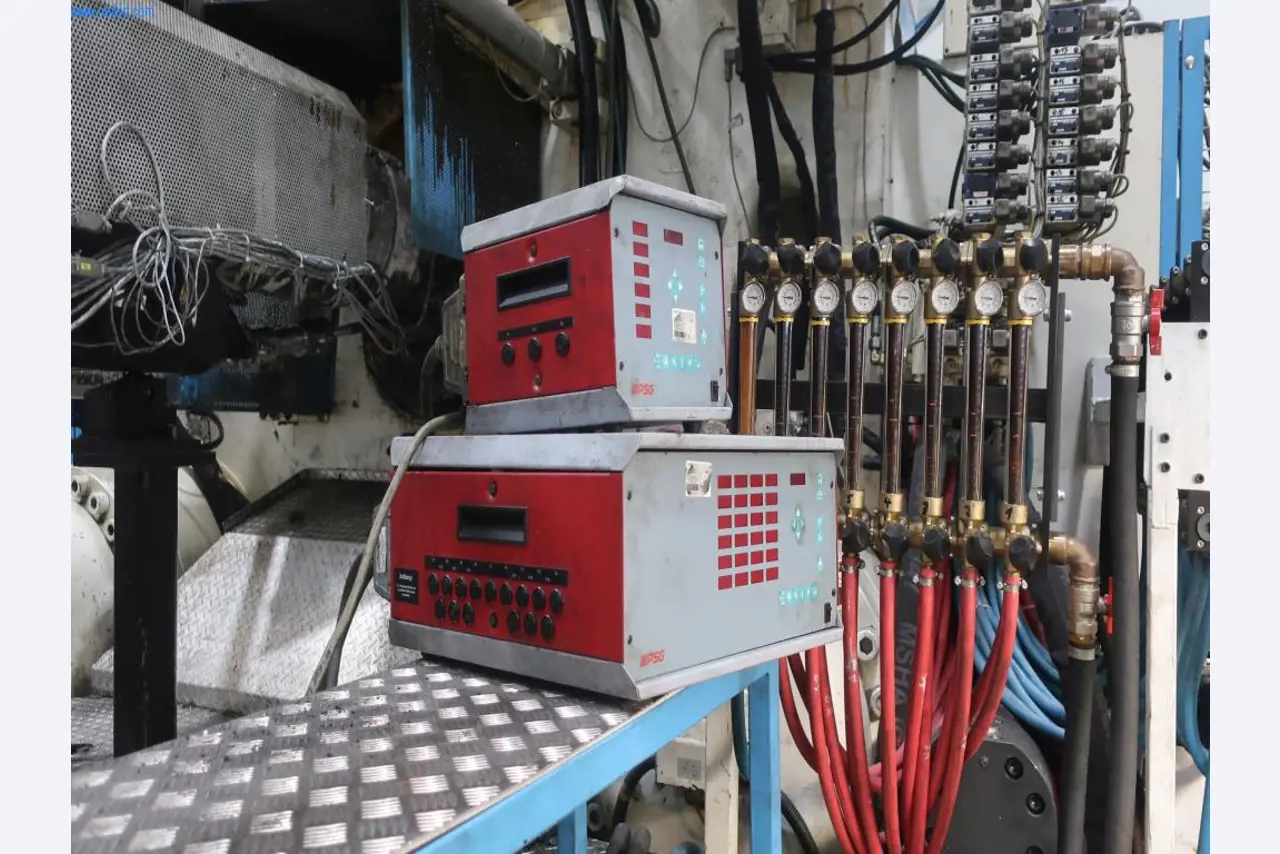

Accessories: paint dosing unit, make Motan, consisting of: Control, type VOLU MC, dosing pot, belt conveyor, belt width approx. 1,200 mm, L approx. 7,000 mm, elevated, mobile, hot runner control unit, make PSG, type HR 06, SN 380805525, connected load 11.5 kW, 6-channel. Hot runner control unit, make PSG, type HR24, SN 420805576, connected load 42 kW, 24-channel, temperature control unit (65), make gwk, type teco bi 150.1.27.12/09, year 2020, SN 40000113464, connected load 29.2 kW, heating/cooling capacity 27 kW/ 200 kW, temp. 140° C, temperature control unit (66), make gwk, type teco bi 150.1.27.12/09, year 2020, SN 40000113465, connected load 29,2 kW, heating/cooling capacity 27 kW/ 200 kW, temp. 140° C

SN 47189, clamping force 23,000 kN, tie bar distance horizontal/vertical 2,000/1,600 mm, clamping platen horizontal/vertical, 2,900/2,500 mm, mold installation height max./min. 2,000/800 mm, mold opening stroke 3,000 mm, total mold weight max. 54 t, centering DS/AS 250/250 mm, crosshead thread M30, injection pressure 16,400 N/cm², injection volume 8,870 cm³, screw Ø 135 mm, cascade 15-fold, core pulls FAP/BAP 2/3, heating circuits Ma/PSG 40/12, metal separator, connected load 560 kW, machine weight 141 t, max. Operating hours 05.614, control, make Engel, linear handling robot, make Engel, type ERC XXL, protective enclosure

Accessories: paint dosing unit, make Motan, consisting of: Control, type VOLU MC, dosing pot, belt conveyor, belt width approx. 1,200 mm, L approx. 7,000 mm, elevated, mobile, hot runner control unit, make PSG, type HR 06, SN 380805525, connected load 11.5 kW, 6-channel. Hot runner control unit, make PSG, type HR24, SN 420805576, connected load 42 kW, 24-channel, temperature control unit (65), make gwk, type teco bi 150.1.27.12/09, year 2020, SN 40000113464, connected load 29.2 kW, heating/cooling capacity 27 kW/ 200 kW, temp. 140° C, temperature control unit (66), make gwk, type teco bi 150.1.27.12/09, year 2020, SN 40000113465, connected load 29,2 kW, heating/cooling capacity 27 kW/ 200 kW, temp. 140° C

Location

- 38228 Salzgitter, John-F.-Kennedy-Str. 50/ Produktionsgebäude/ Halle 3/ Spritzguss

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com