Part of the Auction Automatic warehouse for the food and beverage industry

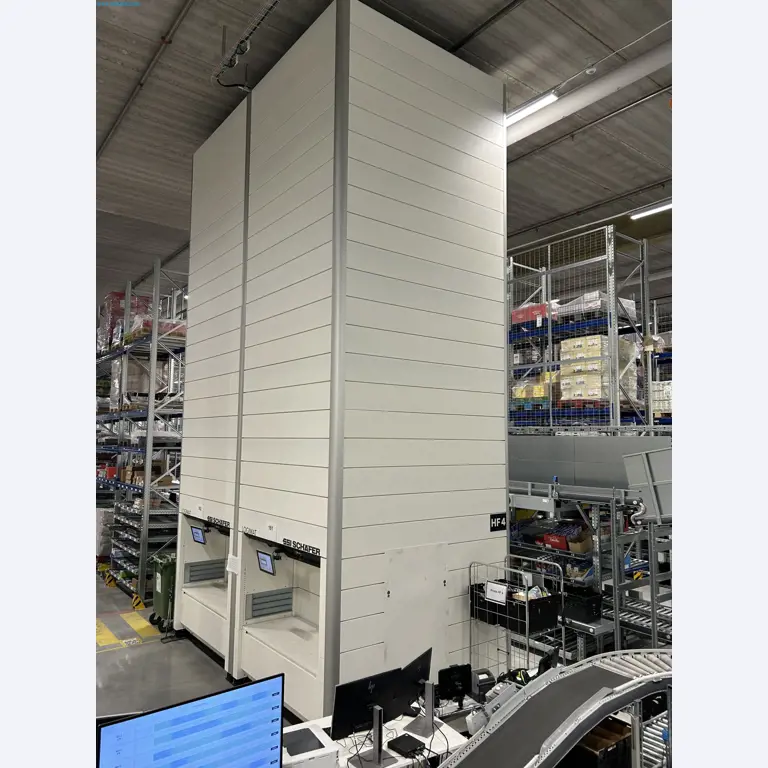

Automatic warehouse for the food and beverage industry (Award subject to reservation) SSI SCHAFER

Trading #18529-1

Details

Product Type

SSI SCHAFER

Construction Year

2020

Description

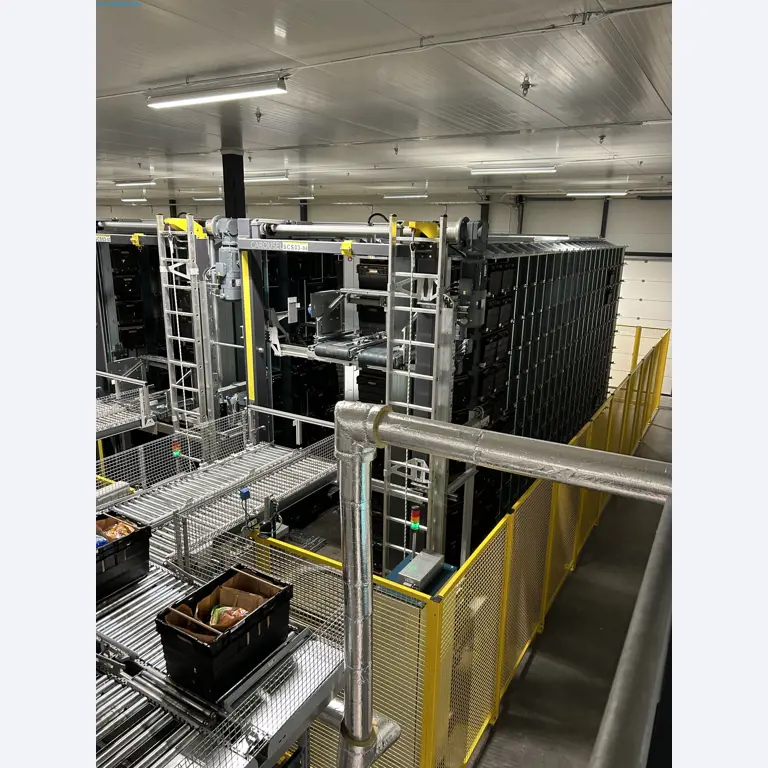

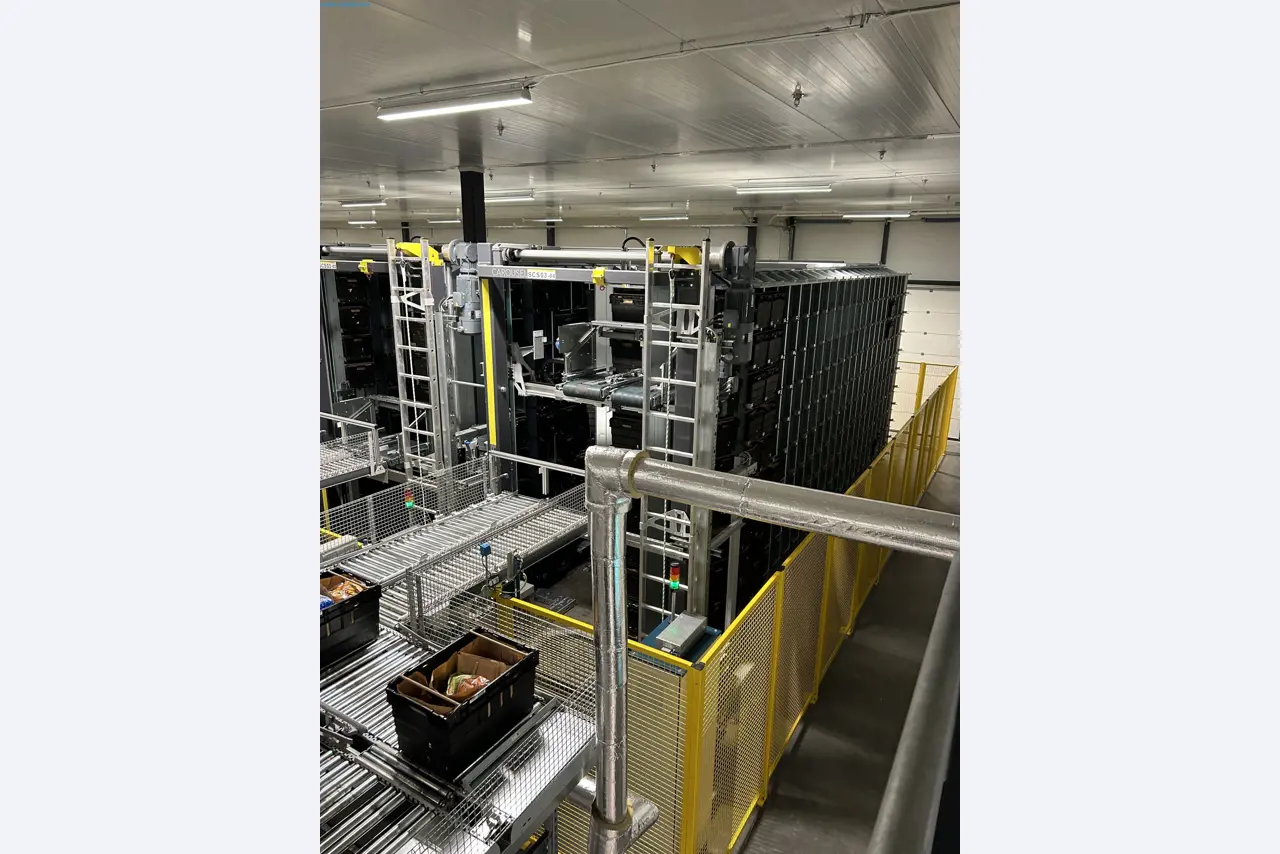

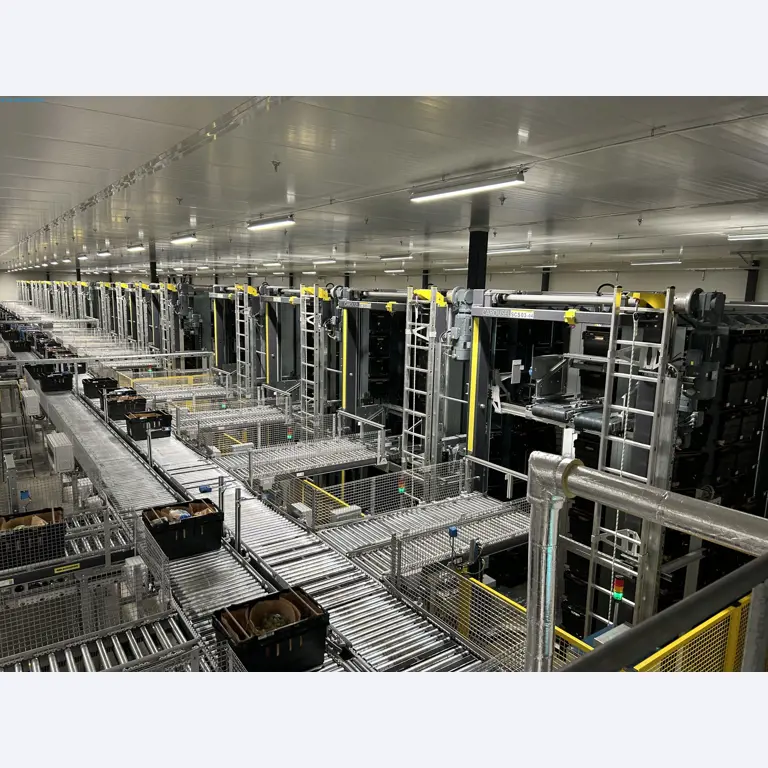

Storage & Handling Systems

Total Storage Locations:

SSI Carousel: 8,800 locations

Flow racks, static shelves, pallet racks, mezzanine

Storage Retrieval Machines (SRM):

SSI Carousel Machines: 20 units

Levels per Carrier: 10

Machine Performance: 205 DC/h

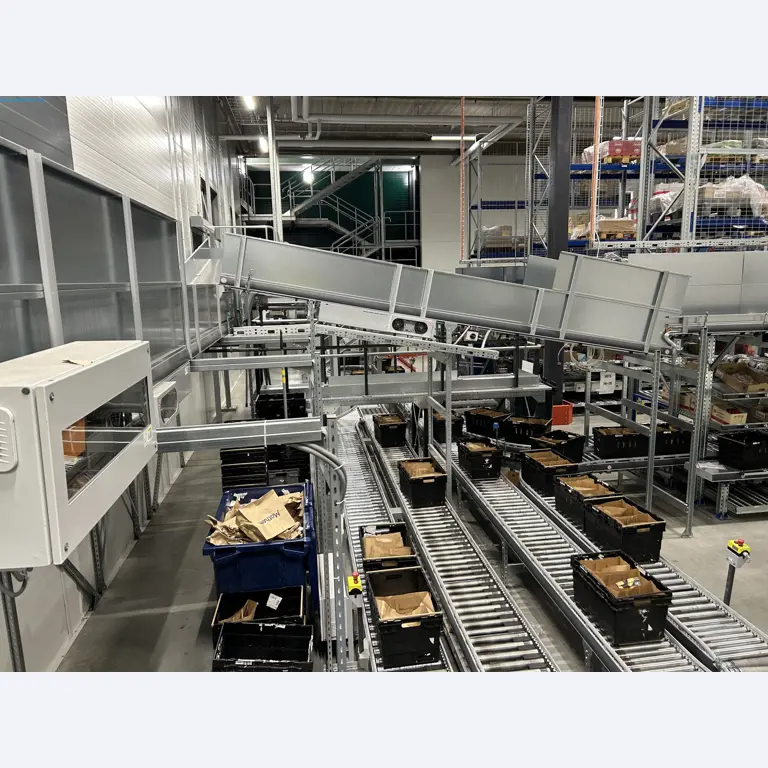

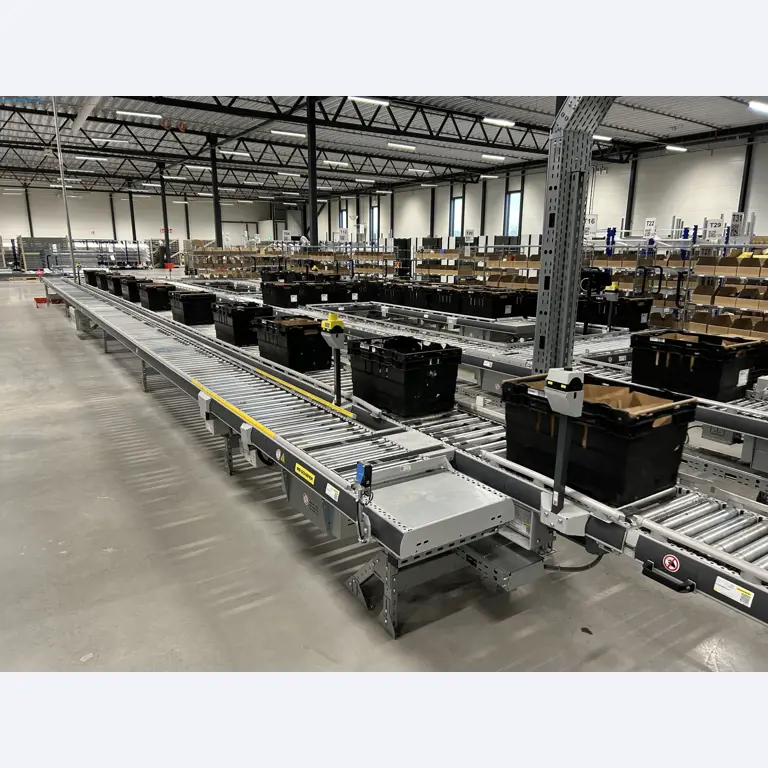

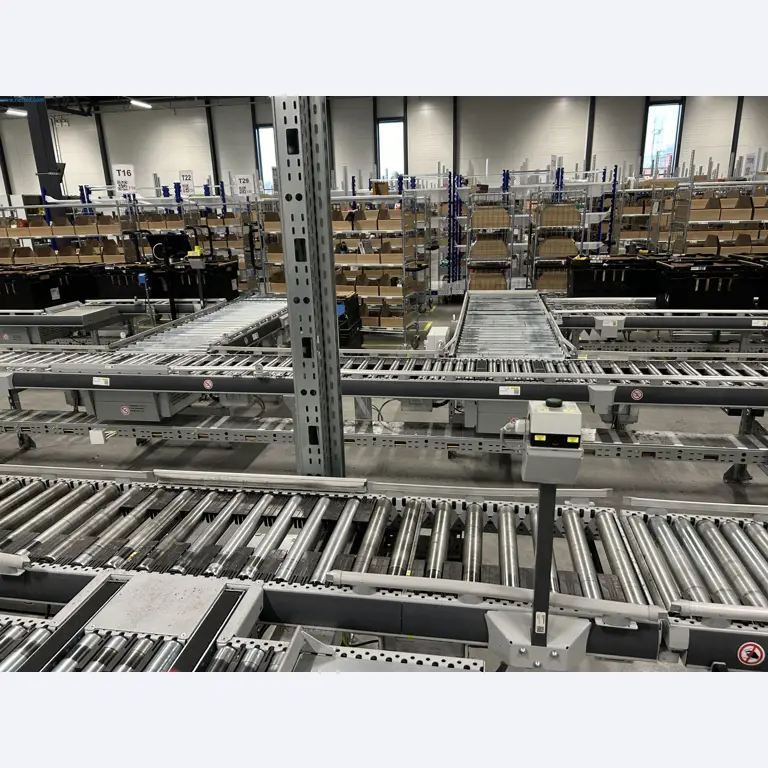

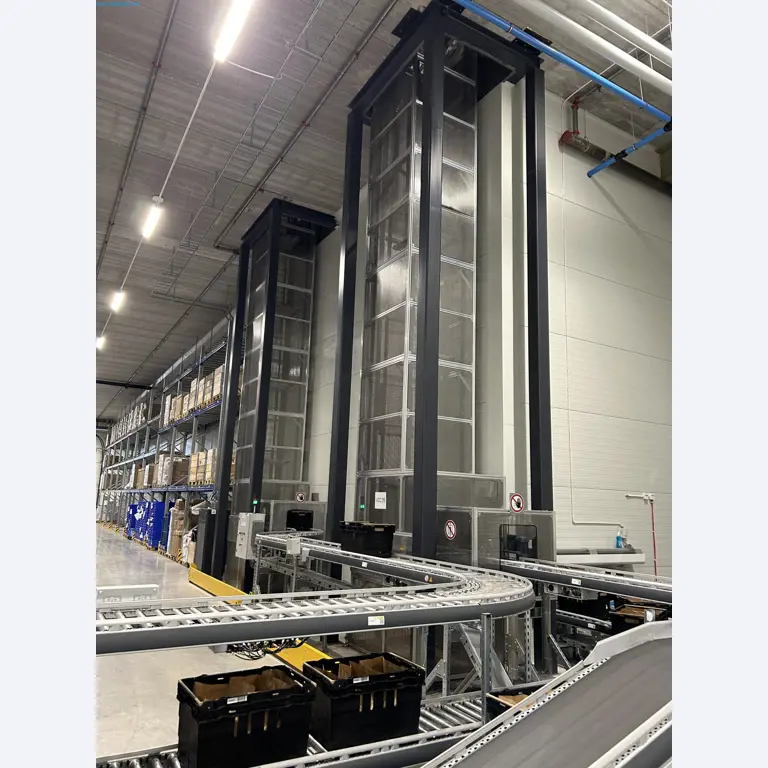

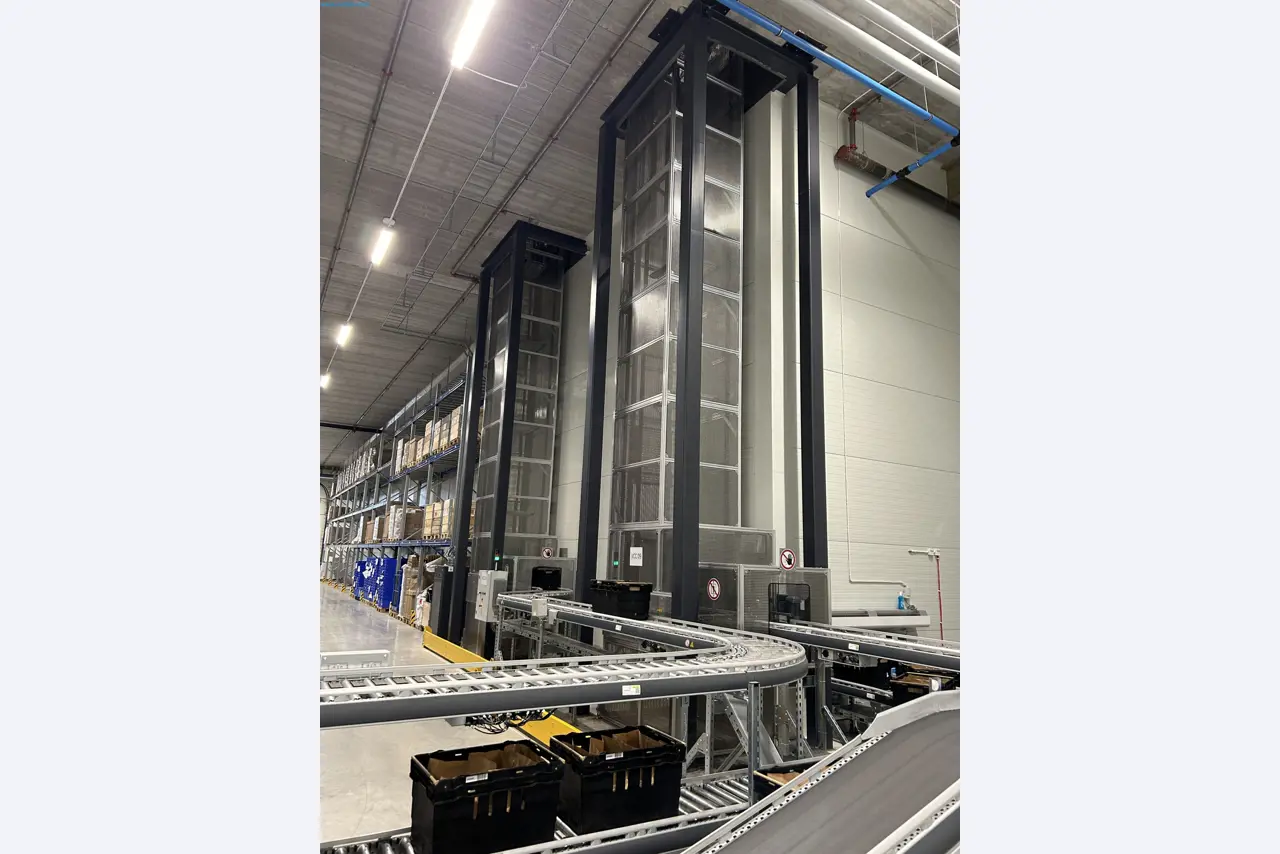

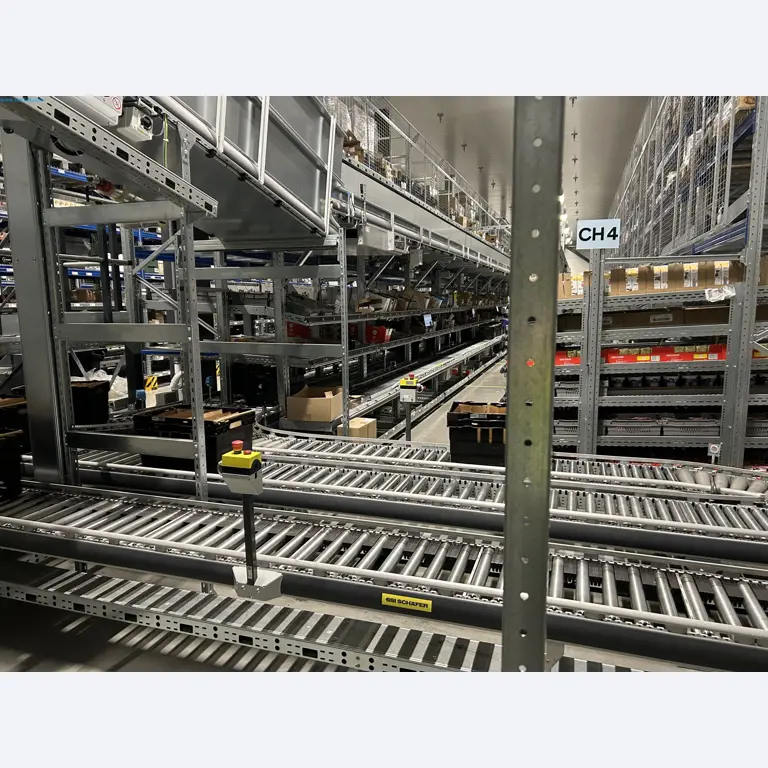

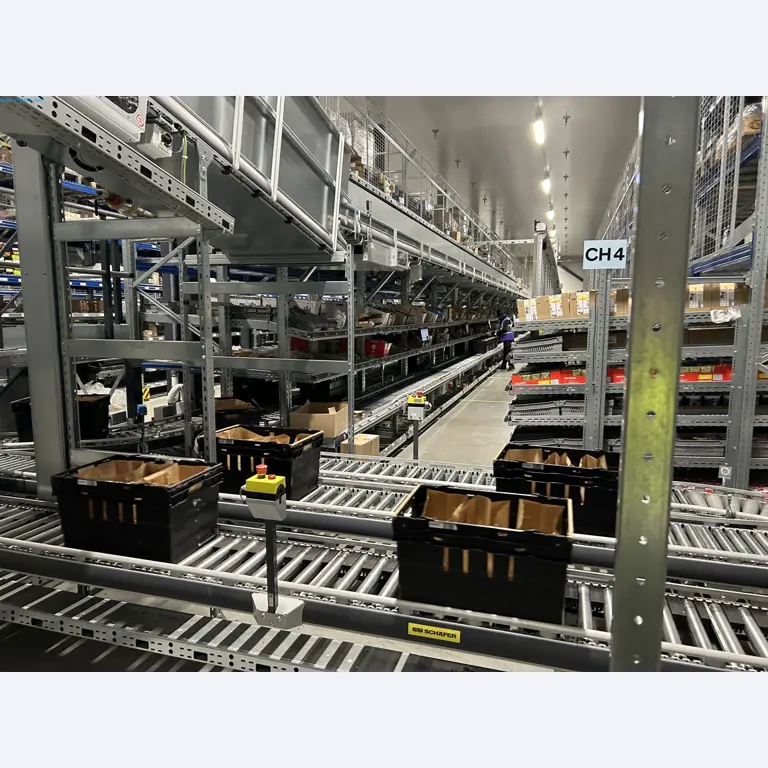

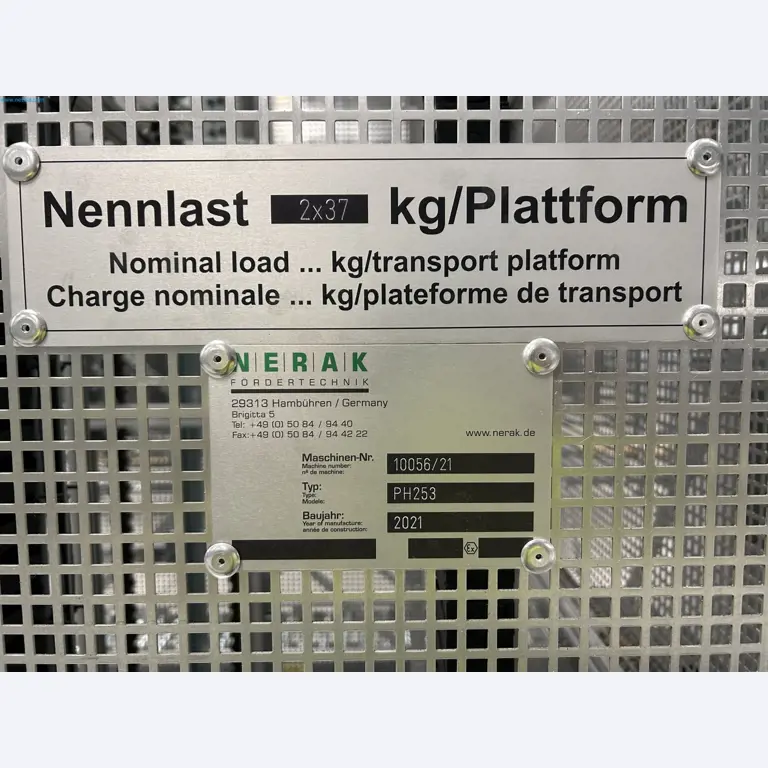

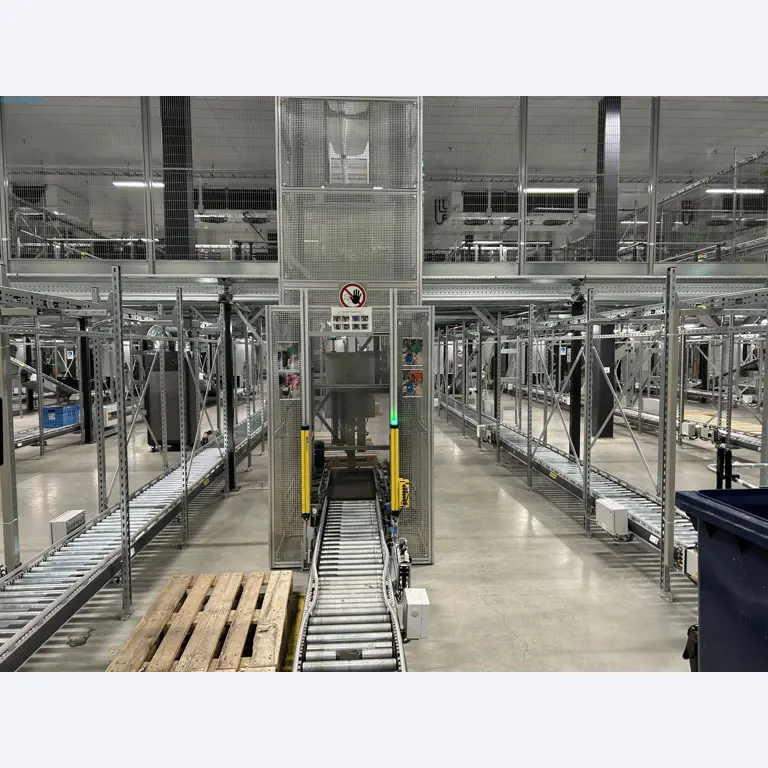

Conveyor System:

Bin & Carton Conveyor System

Vertical Lift Conveyors: 25 units

Bin Stackers: Capacity up to 500 totes/h

De-stackers: Capacity up to 900 totes/h

Conveyor Belt Curve: 6 units, belt speed up to 1.2 m/s

Fire Protection: Not included in the scope; to be determined in later project phases.

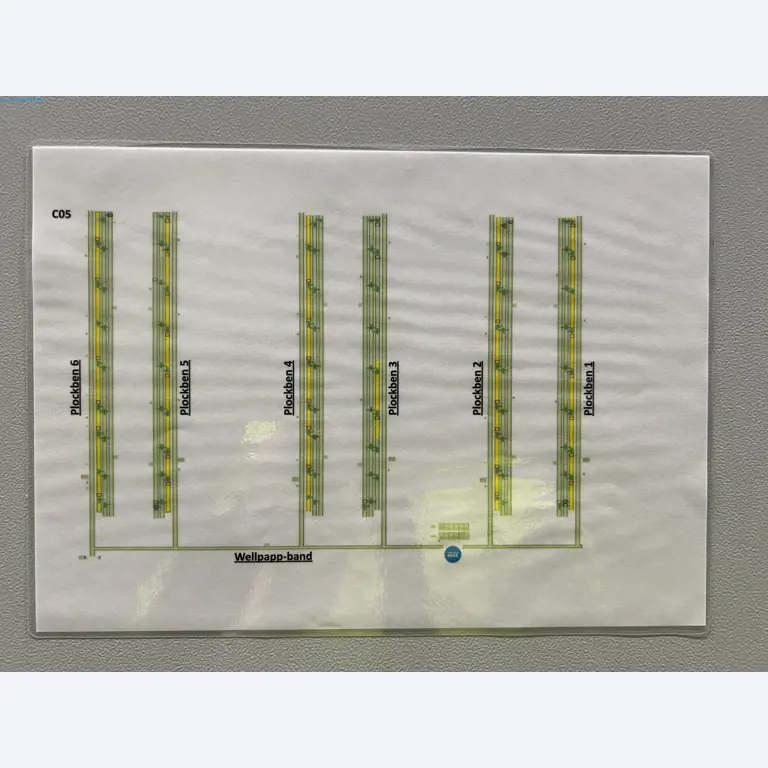

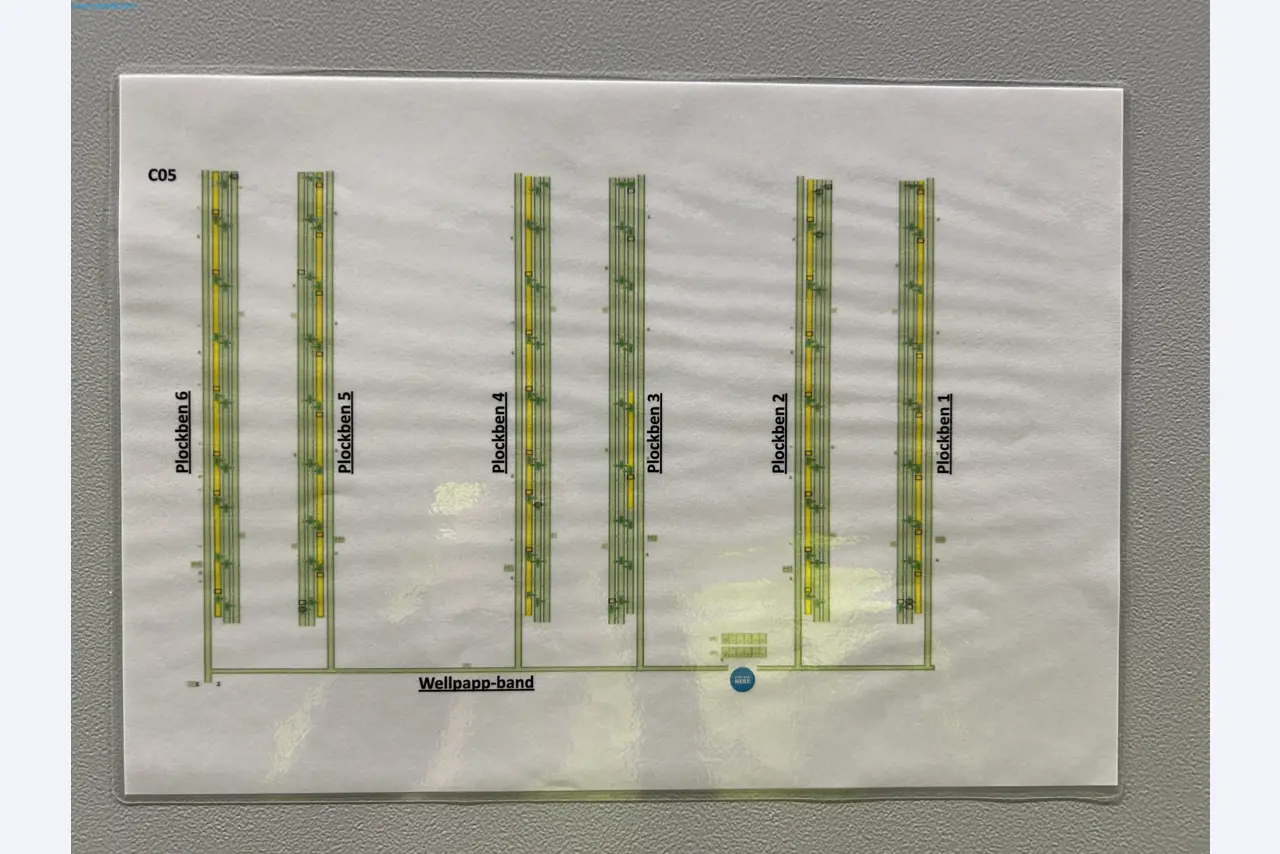

Order & Picking Systems

Picking Methods:

Pick by Light (PBL)

Fast Movers: Picked directly from pallet into order cartons

Semi-fast Movers: Picked from flow channels

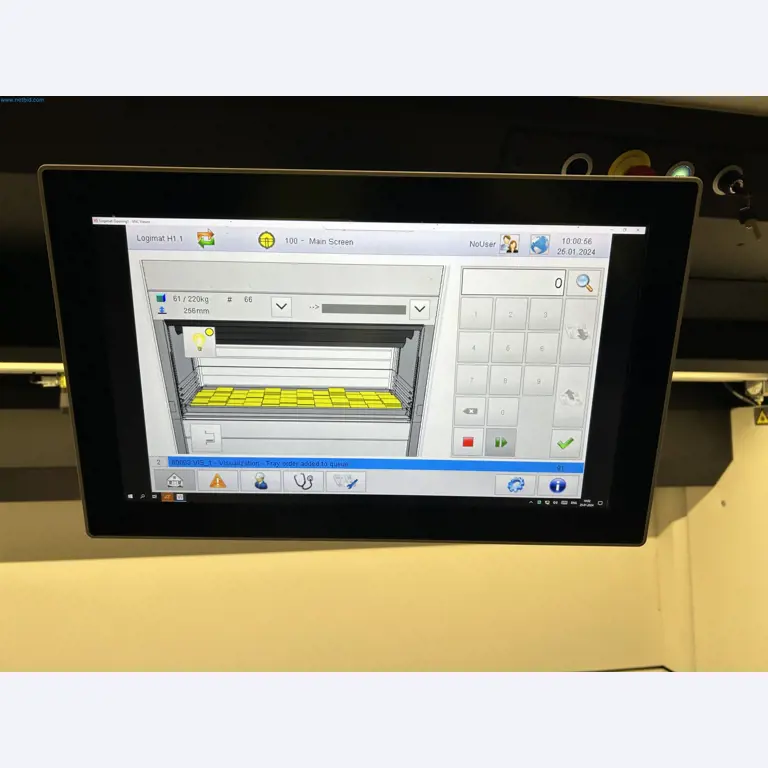

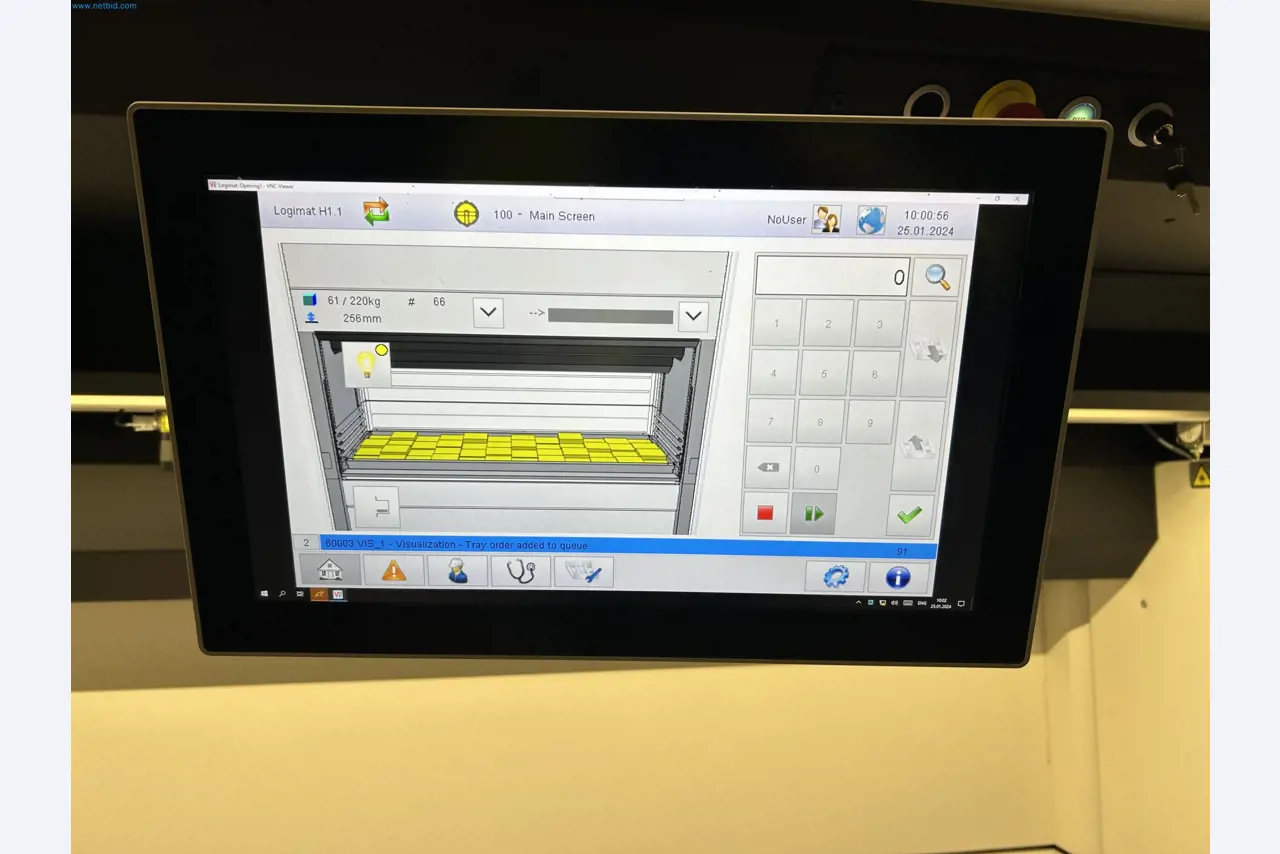

Slow Movers: Picked from Logimats or static shelves

Automation Features:

Order totes with automatic bag inserters

Shipping buffer system for consolidation and sequencing

Sorting & Shipping

Sorting conveyor with sequencing capabilities

Automated tote stacking (4 totes high) for loading

Capacity: 4,400 totes per hour peak output

Operational Performance & Environmental Conditions

Daily Operations:

Average Receiving: 498 pallets/day

Picking Peak Orders: 14,969

Peak Shipping Output: 33,107 totes/day

Temperature Zones:

Dry Goods: +10°C to +25°C

Chilled: +4°C to +8°C

Frozen: -26°C to -18°C

Humidity: 10%-90% non-condensing (EN 60721)

IT & Automation Systems

WAMAS Warehouse Management System (WMS)

Control System: PLC (Siemens S7)

IT Ramp-up Support Available

Remote Maintenance Access for Support

Detail parts list see document.

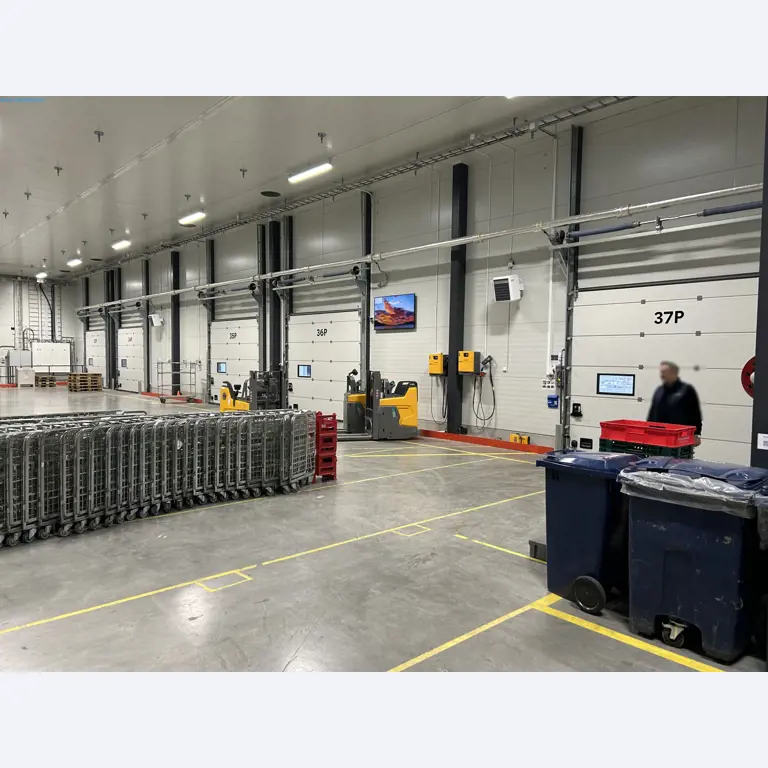

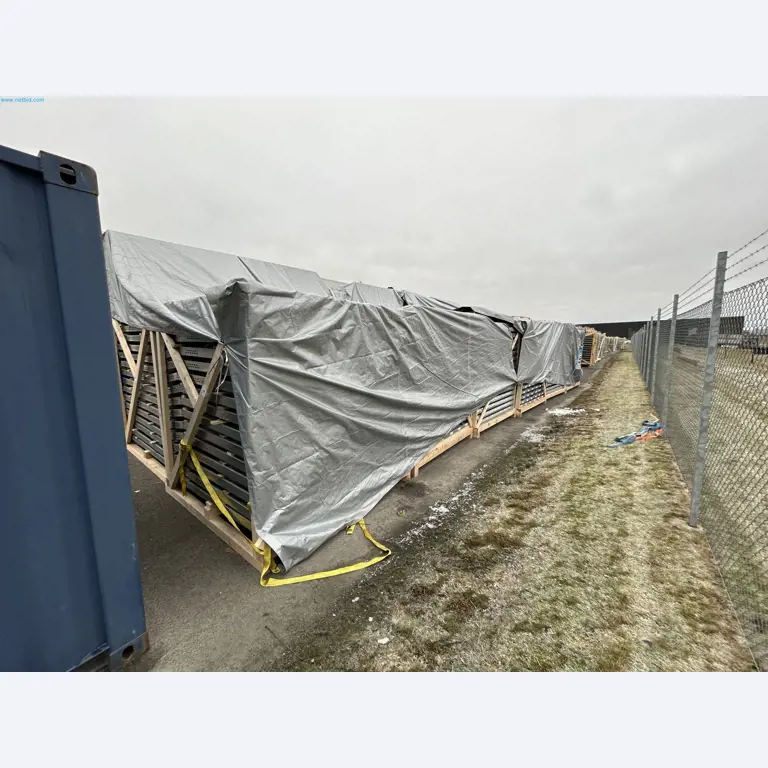

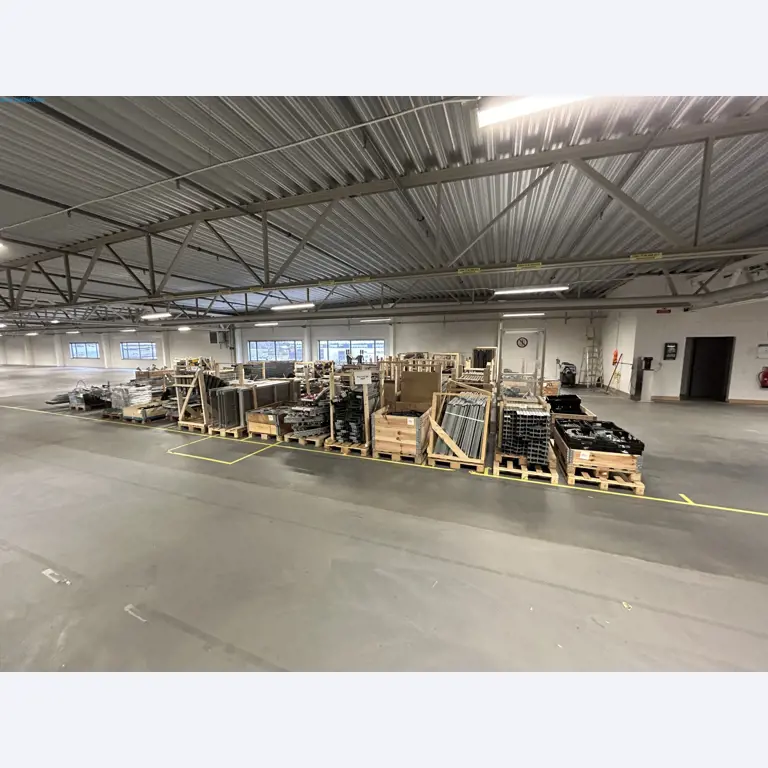

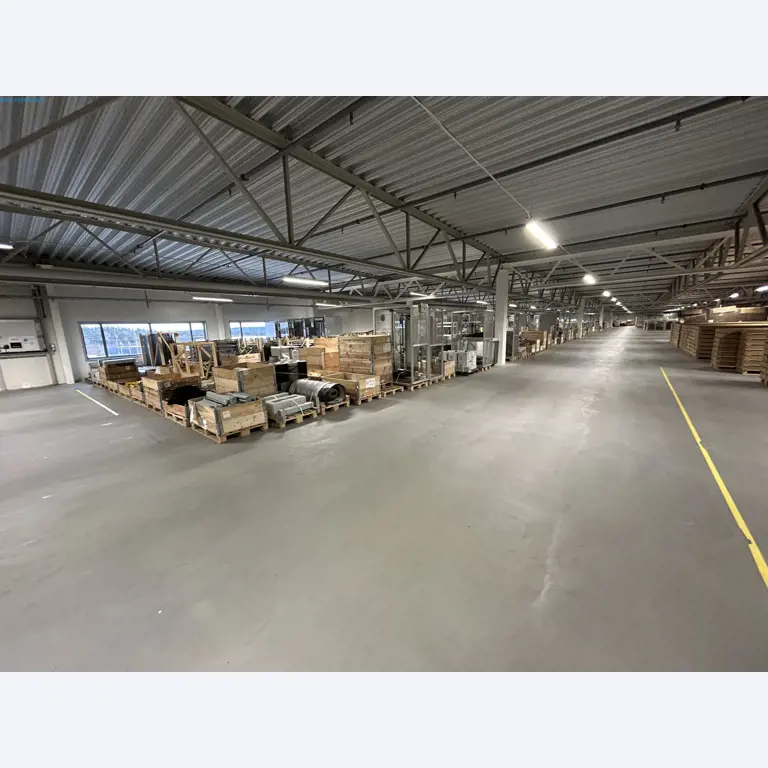

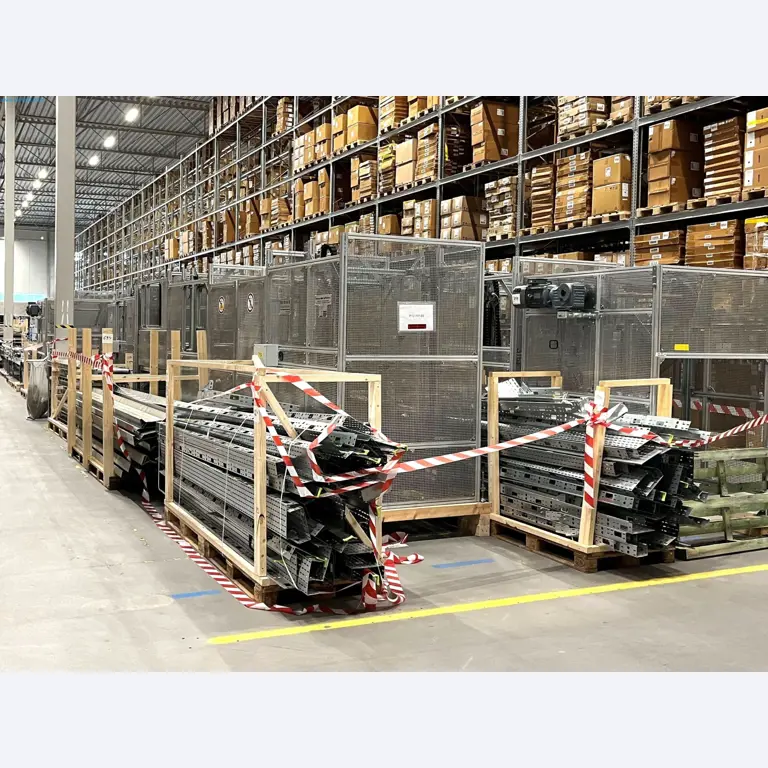

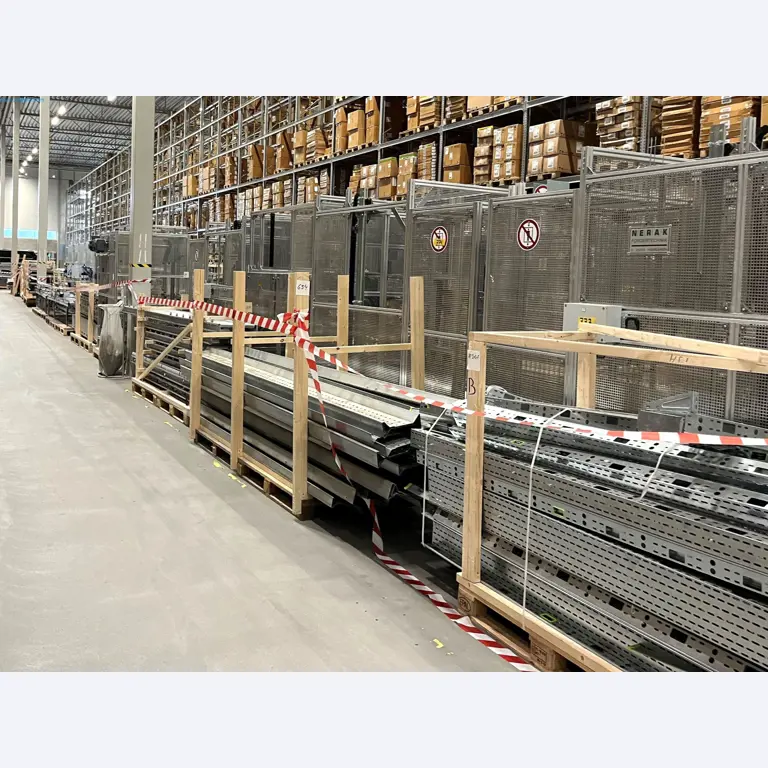

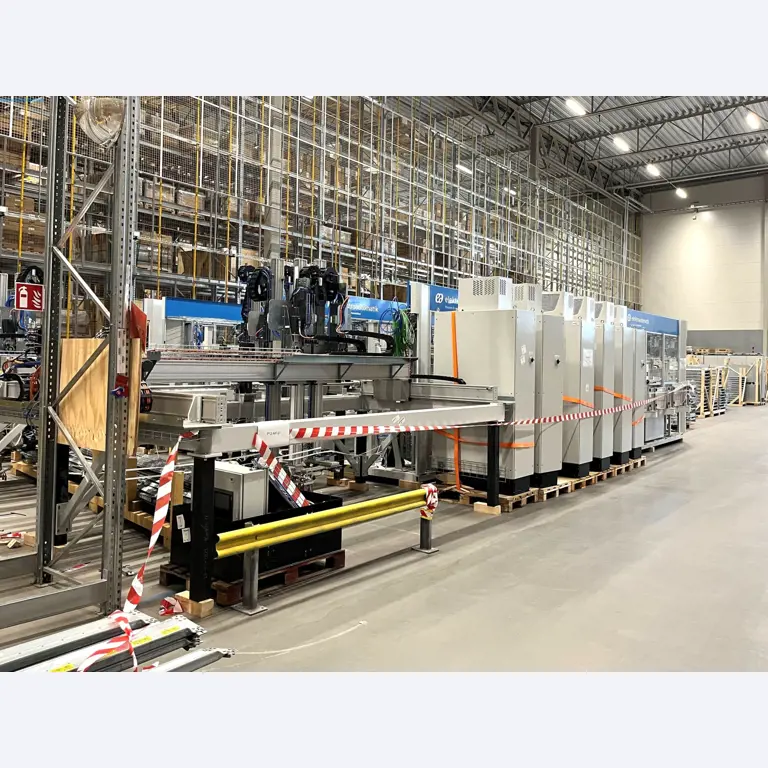

Attention! Everything has been professionally dismantled and carefully stored at two different locations (see photos).

All offers are open to negotiation.

Total Storage Locations:

SSI Carousel: 8,800 locations

Flow racks, static shelves, pallet racks, mezzanine

Storage Retrieval Machines (SRM):

SSI Carousel Machines: 20 units

Levels per Carrier: 10

Machine Performance: 205 DC/h

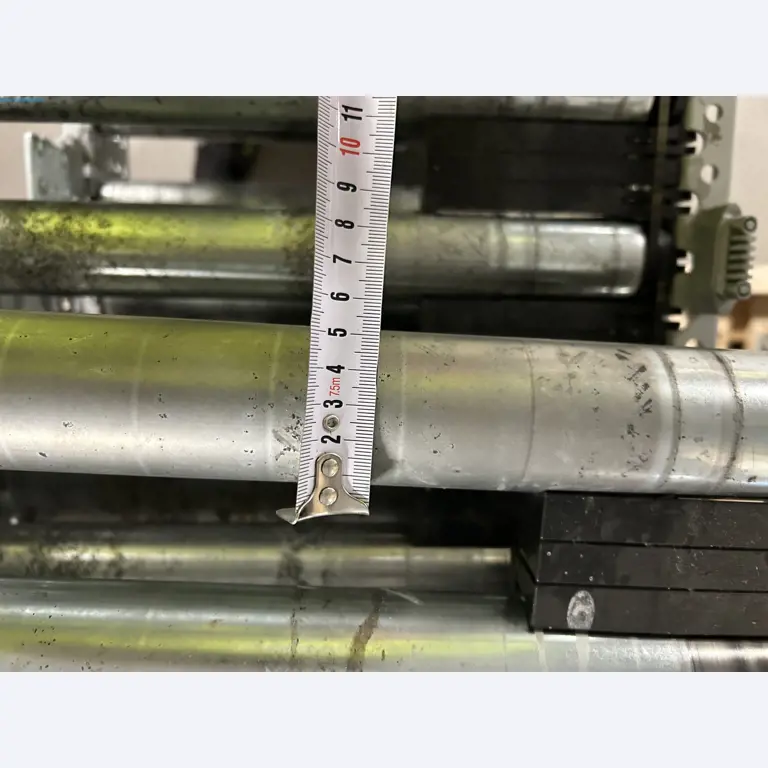

Conveyor System:

Bin & Carton Conveyor System

Vertical Lift Conveyors: 25 units

Bin Stackers: Capacity up to 500 totes/h

De-stackers: Capacity up to 900 totes/h

Conveyor Belt Curve: 6 units, belt speed up to 1.2 m/s

Fire Protection: Not included in the scope; to be determined in later project phases.

Order & Picking Systems

Picking Methods:

Pick by Light (PBL)

Fast Movers: Picked directly from pallet into order cartons

Semi-fast Movers: Picked from flow channels

Slow Movers: Picked from Logimats or static shelves

Automation Features:

Order totes with automatic bag inserters

Shipping buffer system for consolidation and sequencing

Sorting & Shipping

Sorting conveyor with sequencing capabilities

Automated tote stacking (4 totes high) for loading

Capacity: 4,400 totes per hour peak output

Operational Performance & Environmental Conditions

Daily Operations:

Average Receiving: 498 pallets/day

Picking Peak Orders: 14,969

Peak Shipping Output: 33,107 totes/day

Temperature Zones:

Dry Goods: +10°C to +25°C

Chilled: +4°C to +8°C

Frozen: -26°C to -18°C

Humidity: 10%-90% non-condensing (EN 60721)

IT & Automation Systems

WAMAS Warehouse Management System (WMS)

Control System: PLC (Siemens S7)

IT Ramp-up Support Available

Remote Maintenance Access for Support

Detail parts list see document.

Attention! Everything has been professionally dismantled and carefully stored at two different locations (see photos).

All offers are open to negotiation.

Location

- Prognosgatan 12, 504 64 Borås , Sweden / Fryksdalsbacken 9, 123 43 Farsta, Sweden

Dates

Inspection

Only by appointment with Ms. Devrouw - Reyntjens at devrouw-reyntjens@netbid.com.

Pickup

Only by appointment with Ms. Devrouw - Reyntjens at devrouw-reyntjens@netbid.com.

Auction Terms

Special conditions:

The installation is stored in 2 different locations in Sweden: Prognosgatan 12, 504 64 Borås (85 % of the goods for example all conveyors and storage systems) and Fryksdalsbacken 9, 123 43 Farsta (15% of the goods, for example Logimats and carousels).

- No cash accepted at site!

The installation is stored in 2 different locations in Sweden: Prognosgatan 12, 504 64 Borås (85 % of the goods for example all conveyors and storage systems) and Fryksdalsbacken 9, 123 43 Farsta (15% of the goods, for example Logimats and carousels).

- No cash accepted at site!

Contact Person

Country Manager Benelux & France

Alexandra Devrouw-Reyntjens

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com